Here is the second part of the starter motor removal, some of you may want to have a professional perform this, some will follow along just fine.

We left off with basically external work and a bit more than 2 pounds of weight removed, now we go for the rest.

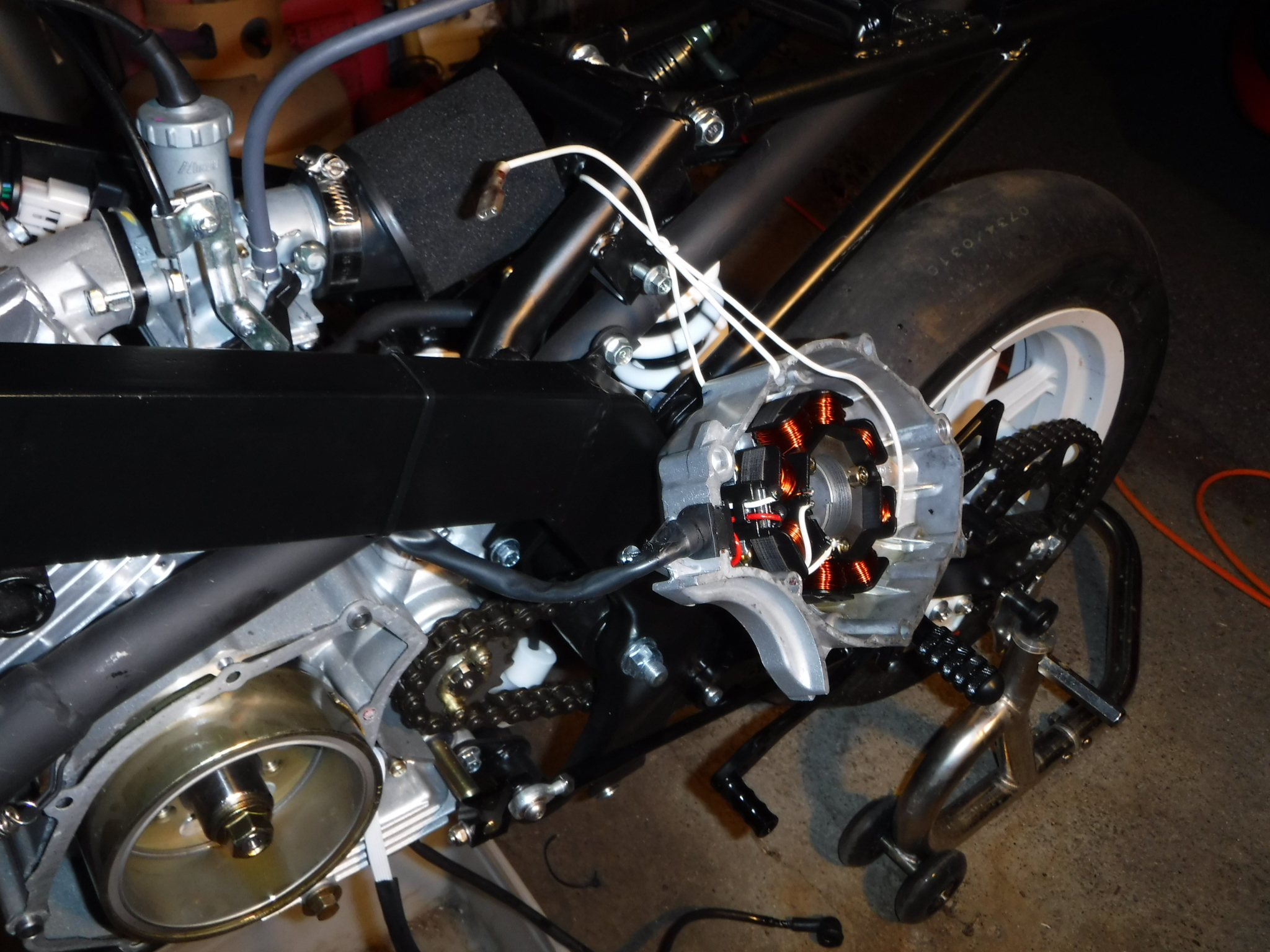

Crack the cover off the left side of the engine, you'll want an 8mm socket and a power tool makes this go faster. I hung this cover with the stator from the frame with a piece of wire.

Then blasted the nut off the flywheel with an impact, it should only be about 53 foot pounds of torque tight, so just about any of the impacts will bust it loose.

You'll need a puller of some sort to force the flywheel off the taper shaft.

What you see after it pops off. Some of the start clutch pieces may fall out, don't worry, you won't be using them again.

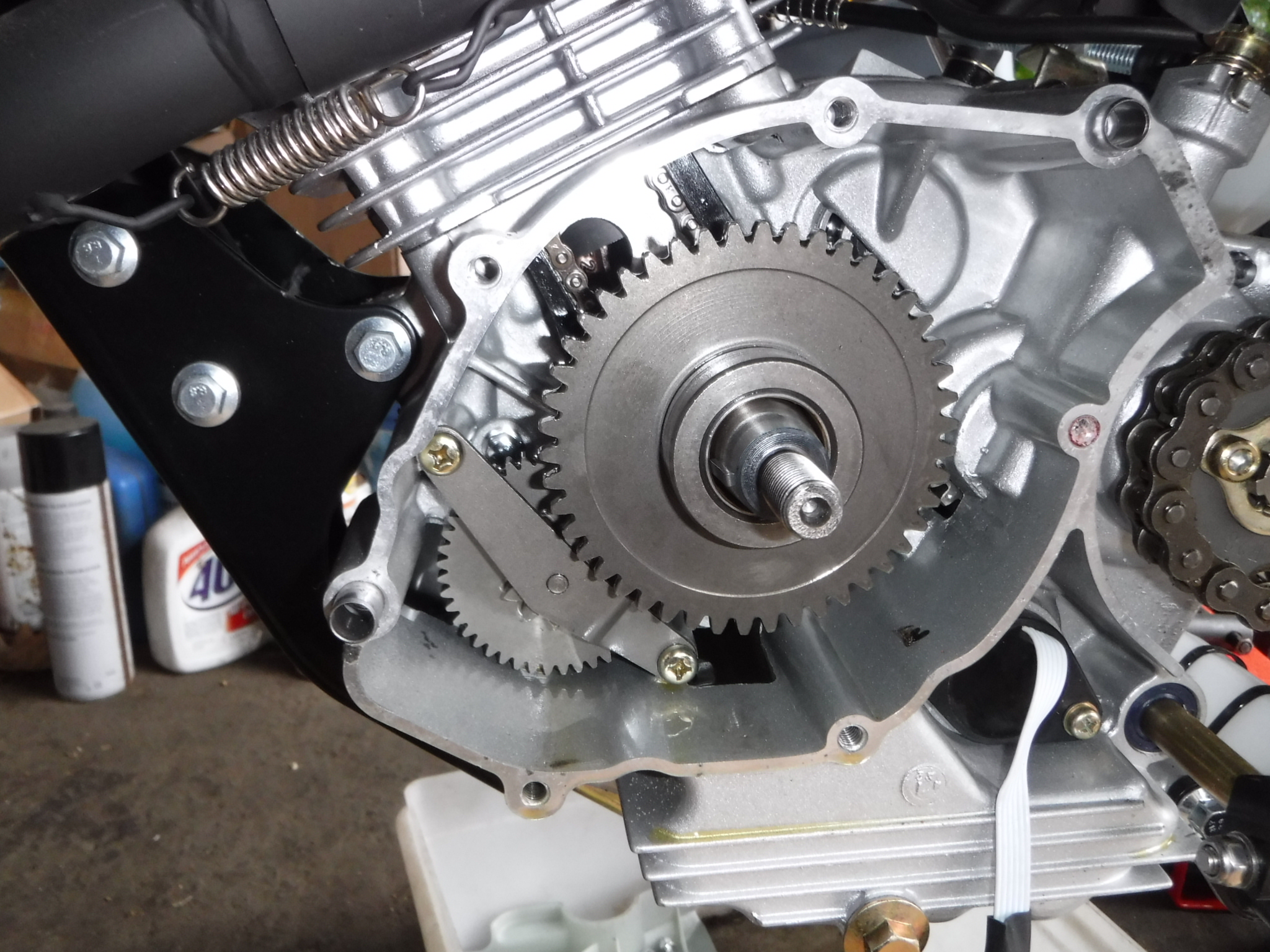

Inside the engine case you can see the gears that also need to come out. Drive gear, idler gear, and small spacer. When all that is gone. you'll have direct line of sight to the cam chain sprocket and chain.

Now the hard part, the bolts that hold the starter clutch to the flywheel have been "staked" so they can't rotate. You'll need to drill the ends off, you can be fairly brutal with the drill because you'll still have the other 3 holes to use with the puller. Then just unscrew the bolts and the starter clutch is free.

You can see why I didn't want to drill, all the chips stick to the magnets and are difficult to to remove.

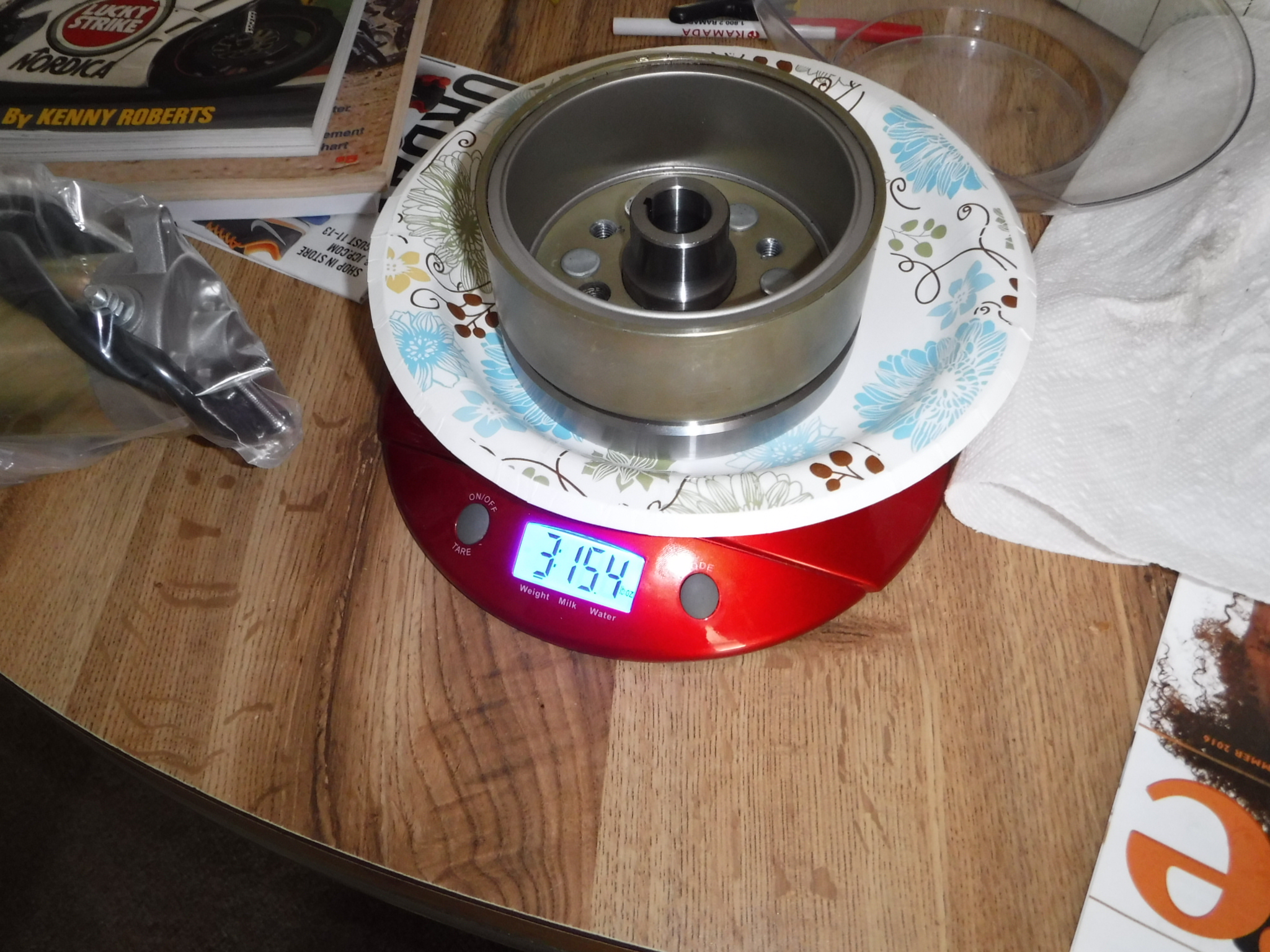

Time to tally the weights

2 pounds and 2.4 ounces of additional weight, and a large part of that is rotating mass attached to the flywheel. That should let it spin up quicker, but of course I won't be stopping there.

Total weight of all the starter components is a bit over 5 pounds.

And the flywheel weight, I'll be getting back to this in the future to lighten it as much as possible without causing any problems with the engine running or starting. Need to check on some rules before proceeding.

Searching through TTR125 forums, it looks like another 20 ounces can be removed. With almost 4 pounds of weight the 20 ounces removed would be nice. Re-assembly not shown but put the flywheel back on and torque to about 53 foot-pounds. The cover screws should be torqued to about 12 foot-pounds.